Taylor APO Dual Auger Bagging System with Weight Controller, Hopper Containment and Superstructure

Taylor Dual Auger Packer/Bagger

The Taylor Model APO Dual is designed with variable speed augers to allow bulk / dribble bag filling. The dual auger technology allows the packer to feed material at three sequential speed settings which produces faster and more accurate measurements while filling open mouth bags. Packer is capable of handling a wide spectrum of materials from free-flowing to non clumping powders and granules.

- 15 to 125 lbs bags

- Up to 6 bags per minute

- Product agitator and clean out door are standard

- Dual augers provide bulk / dribble flow

- Inflatable spout provides positive seal during fill cycle

- Stainless Steel contacts with food grade finish

Products typically handled with a Dual auger packer system:

- Free flowing, Non-clumping powders

- Flour

- Fine Powders

- Fish Meal

- Granules

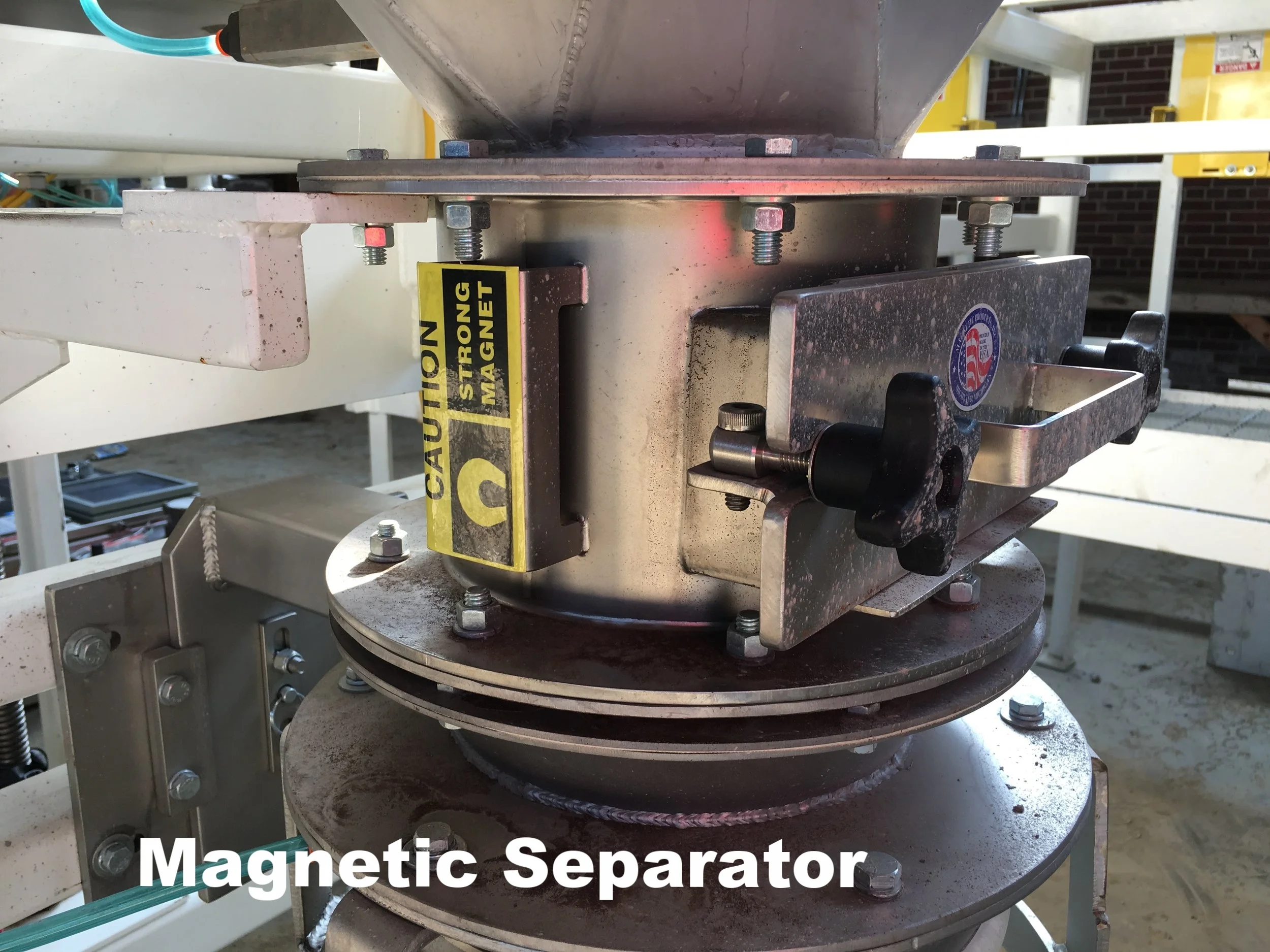

Weight Controller, Control Panel and Primary Magnetic Separator

All material handling and weight controls are located on a centrally located panel. The T3000 weight controller seen above will provide ease of use when configuring, networking, calibrating, and storing information. Built-in features such as Auto Fast Feed Adjust, self-adjusting presets, and self-regulating jog functions automatically tune and simplify your process while providing accurate weight measurement. Because these features consistently monitor and improve product throughput, you can focus on the bigger picture.

- Application specific for more control

- Connect to common plant network as DeviceNet Master

- Functions as gateway between networks

- Input / output anywhere on the network saves setup and wiring time and cost

- Built-in web server

- PDA-link interface downloads and uploads data from a PDA

- Smart Diagnostics isolates system problems from control room

- WAVERSAVER® compensates for vibrations near scales

- SMM (Secure Memory Module) backs up configuration data for easy transfer

- Predefined or custom event Email notification

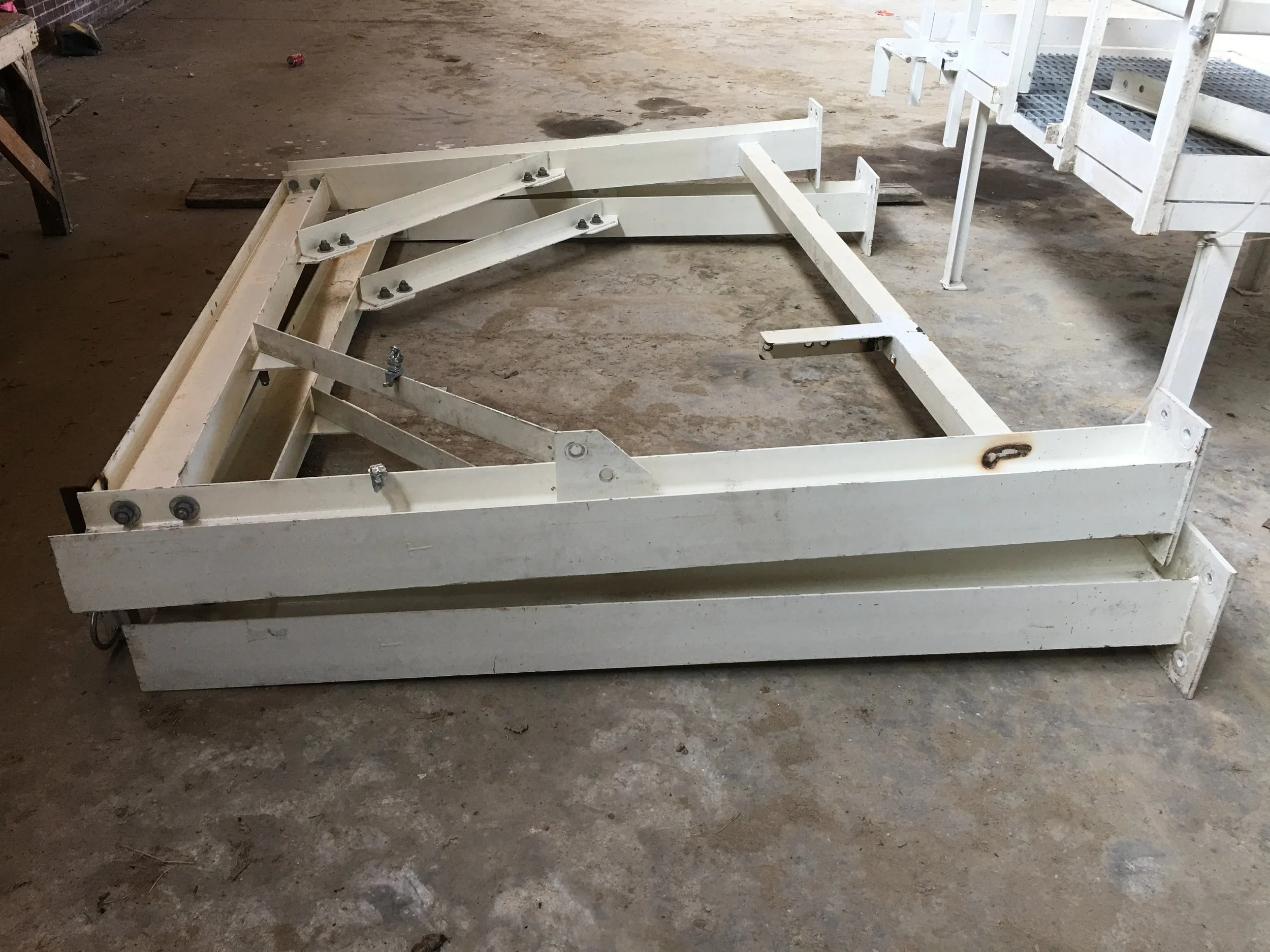

249 Cubic Foot Hopper, Pneumatic Conveying System, and

249 Cubic Foot Hopper

This hopper when assembled to the provided superstructure ensures you will be bagging without interruption for extended periods of time. The hopper mounts above the bagger system with the included superstructure.

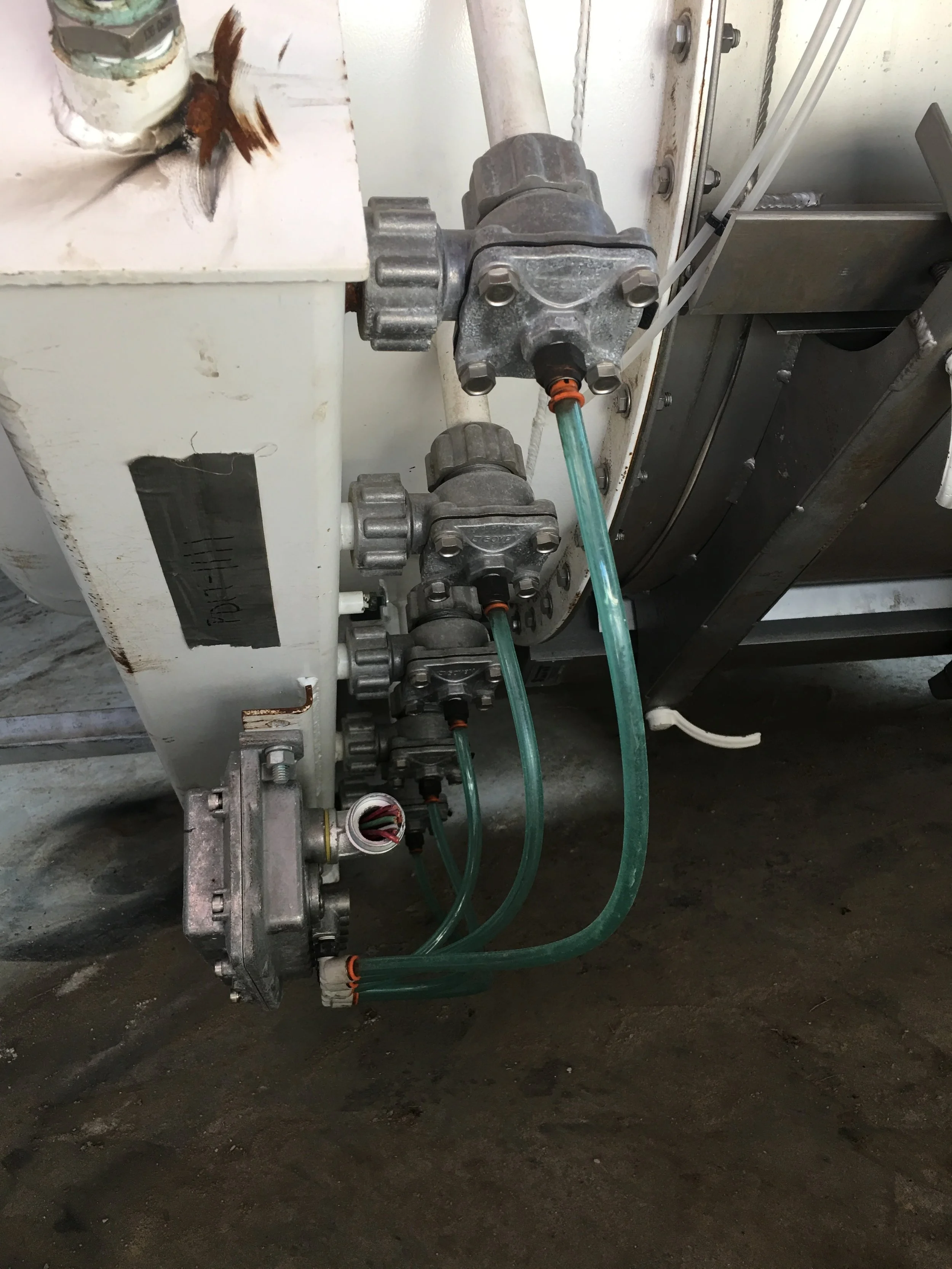

Pneumatic Conveying System

This purchase includes components to allow you move material pneumatically in your plant. The purchase includes the 249 cubic foot hopper, a pneumatic filter receiver (12' x 4'), 2 Smoot Rotary Valves to control material flow. See pictures below.